Ensure Compliance with the Fire Regulations

Online Quotation

Located Solihull, Birmingham Area.

Main areas covered include - Coventry, Stoke, Nottingham, Leicester, Stafford, Shrewsbury, Telford, Milton Keynes, Oxford, Luton, Uxbridge, Hemel Hempstead, Banbury. Gloucester, Wolverhampton, Worcester, Northampton, Derby, Hereford

See Genuine Valid Google Customer Reviews Below

Control of Contractors

Control of contractors and Hot Works.

Appropriate control of contractors is very important if you are planning works within your premises. For example building extensions, new heating equipment, or major refurbishment then it is highly likely that you will be employing contractors. The risk of a fire is higher during these works from increased electrical use, hot works (open flame tools) and increased fire loading from building materials etc.

There are some procedures that should be put in place. Firstly you should ask the contractors for a copy of the Risk Assessments and Method Statements (known as the RAMS). Risk Assessment Method Statements (RAMS) are however, not required by law. Safety method statements are most often found in the construction sector and are useful for higher-risk, complex or unusual work such as the use of hazardous substances. Ensure the contractors are insured.

All staff should be briefed on the works that are taking place and the safety measures that are required. RAMS are helpful for providing important information to employees about how the work should be done and the precautions to be taken, as well as providing the principal contractor with information to develop a health and safety plan for the construction phase of a project. Safety method statements aren’t critical; however, it is essential to make sure that risks are controlled.

When the works take place ensure there are regular site inspections to enforce the rules that have been put in place. including not obstructing fire extinguishes or fire alarm call points, and keeping the escape routes clear at all times. An the end of the day inspect the premises to ensure there are no non-essential electrical items left on site, the site is clean and tidy with minimal accumulation of rubbish and there are no materials left outside that will be of use to an arsonist.

Managing Contractors Online Course

This recommended Managing and Control of Contractors online training course explains exactly what your business and contractors are required to do regarding health and safety procedures. It explains how to consider the risks associated with contractors’ work and create an appropriate plan to control them. Furthermore, it emphasises the importance of communicating and coordinating with your contractors to make the work as efficient and safe as possible.

By law, any business that hires contractors to work on their premises becomes responsible for their health and safety. If you are in charge of managing health and safety in your workplace, this applies to you. You and the contractors both have joint responsibilities however, so it’s important to know what health and safety law requires from each of you.The course is accredited by CPD and approved by RoSPA with a full certificate on completion.See Full Details

Hot Work Permits

Due to the fire risks involved with hot works. According to BS9999 preparing a permit to work is mandatory for the control of contractors. BS9999 states that - A hot work permit procedure, which may be part of an overarching safe system of work/permit to work procedure, should be followed before any hot work is allowed in or near a building.

When one considers the number of highly damaging fires that have been caused by lack of proper procedures and control of contractors it is not surprising.

Recent Fires caused by Inadequate Hot Work Procedures and control of contractors.

1/ This fire occurred during the school summer holidays. Plastic tarpaulin caught light as a gas torch was being used, and the fire spread rapidly, destroying much of the school. Subsequent investigations identified a number of failings that meant the risk of a fire occurring had not been adequately addressed.

The biggest issue in this incident was that there was no hot work permit in place to ensure the works were being managed safely.

In addition to that, materials were being stored on the roof where the works were taking place and there was no fire extinguisher on site.The absence of a fire extinguisher may have put the contractor in breach of their Hot Works Warranty, as their insurer refused to indemnify them following the loss.

2/ Hot work permits specify that for torch-applied roofing, a fire watch must remain in place for at least an hour after work has finished for the day, to ensure all sparks and embers in the site area have been extinguished.

In this incident, we believe the contractor left the site before the one-hour fire watch period had elapsed, and it was during this time that a fire took hold. Had the contractor stayed on site, the damage could have been minimised considerably.

Although there was a hot work permit in place on this occasion, it was the contractor’s permit, and nobody from the school had oversight of it. It may also have been possible for cold works to have been used instead, but no explanation was given as to why this option was not chosen.

3/ This fire occurred at a particularly sensitive time – as students were returning to school to collect their GCSE results.

Combustible materials caught light as maintenance work was taking place on the roof of a two-storey building that housed a library and IT facilities. Although the fire was spotted quickly, it spread so rapidly that the whole of the building was destroyed.

Although there was a hot work permit in place, managed by the contractor, it didn’t achieve a great deal and appeared to be more of a box-ticking exercise. One of the problems identified was that it was a generic permit for a larger programme of works taking place at the school and the permit wasn’t specifically created to manage the risks associated with hot works. In addition, there was no proper oversight of the permit. It was kept in the contractor’s cabin and the only person who saw it was the individual who had issued it.

The above are actual investigations and confirm the importance of correct control of contractors and procedures carried out by Zurich Insurance Insurance.

*Common types of hot work include:

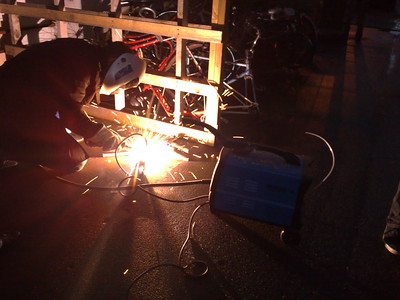

*Welding, brazing, and soldering.

*Grinding and cutting.

*Thawing pipes.

*The use of open flames, blow-lamps, and torches.

*Using bitumen and tar boilers.

*The use of hot air blowers and lead heaters.

This is not an exhaustive list, but it does include the most common examples of hot work and those that can pose significant risks without proper safety precautions.

Hot Work Hazards

Sparks. are the main risk with by hot works. Sparks can easily get trapped in cracks, pipes, gaps, holes, and other small openings, where it could potentially smoulder and start a fire.

Flammable cinder, slag, swarf, molten metals,and filings. The debris and residue that hot work creates are often highly combustible and/or hot.

Hot work can cause a pipe to heat up substantially and this heat can easily transfer through the process of conduction to another, potentially flammable surface and cause a fire.

Ensure flammable materials or substances are removed from the area before work, they could come into contact with a surface that has become hot during the work and easily start a fire.

In certain environments, there may be vapours or gases in the air that are highly combustible and could ignite when exposed to hot work. Hot work could generate fumes that create an explosive atmosphere. Ensure all of the above is included in your procedures for the control of contractors.

Welding Online Safety Training Course

This recommended Welding Health and Safety training course raises awareness of the risks presented by welding operations, including both gas and electric arc welding. It provides details of how to complete a risk assessment and follow the appropriate control of contractors measures.

Welding and cutting operations are used in many manufacturing and engineering environments but they present many risks to health and safety. This course helps you to understand the risks that must be avoided and provides knowledge of how to carry out your welding activities safely.The course is accredited by CPD and approved by RoSPA with a full certificate on completion. See Full Details.

How to prepare a Hot Work Permit

Before hot works are carried out in your premises you should prepare a Permit to Work which will ensure that a safe working system is in place.

The sections that a permit generally must include are:

*Details of the work involved. What type of hot work will be taking place?

*Hazards and risks. What are the associated risks of the hot work?

*Precautions and procedures. What precautions and procedures and control of contractors will you put in place and apply before and during the work?

*Do people need to wear protective goggles, face masks, gloves, etc?

*With reference to isolation certificates, does any nearby equipment need isolating before work can start?

*This includes those involved in creating, implementing, and following the permit.

*Do people need any training before they can carry out the hot work? This is an important part of the control of contractors procedures.

*If the people doing the work swap shifts, what procedure will your workplace follow to ensure they change over safely?

*Once the work is completed or needs cancelling, who is responsible for managing this?

If there is a full understanding of the work involved and who’s involved, a permit is fairly straightforward to prepare. A competent person who isn’t directly involved in the hot work must prepare and authorise the plan, but the input and commitment from everyone taking part in the work is still necessary.

Permit to Work Online Course

This recommended course will explain the purpose of permits to work and what type of high risk activities may require them. It looks at what sections a permit should contain, who has the responsibility for preparing them, and what the duties are of everyone who will need to carry out work covered by a permit. On completion of the course, learners will understand how to prepare a permit, or follow it if their workplace receives one, so they can ensure everyone carries out high risk work safely and there is adequate control of contractors. The course is accredited by CPD and approved by RoSPA with a full certificate on completion. See Full Details

Useful Further Information Link